KIT HISTORY – NSN 1680-01-065-6644

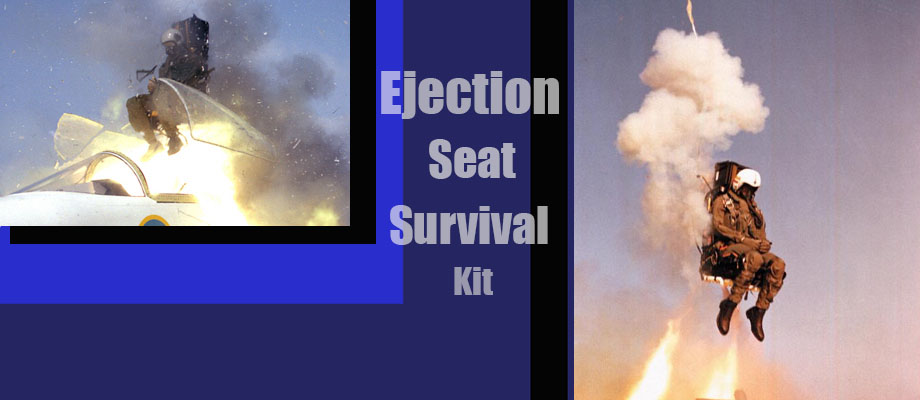

THE CNU-129/P SURVIVAL KIT STORY

In 1974 the United States Airforce contracted H. Koch & Sons Co.’s engineering group to design the new CNU-129/P Survival Kit Container for the USAF B-52. F-5 and T-38 aircraft as well as Allied Nation ejection seat systems. In the 1950’s and 1960’s, Koch developed and produced virtually all of the rigid seat survival kits for USAF and many other Air Forces world-wide. The CNU-129/P incorporated many of the features that had proven successful in earlier kits, including the automatic deployment system which allowed an incapacitated aircrew member to effect complete seat-man separation at ejection. The new kit featured a number of redundant features which would provide the crewmember with back up provisions to ensure a successful ejection as well as providing the necessary gear for survival in nearly any environment on land or at sea. Development testing was conducted at the Navy’s International Drop Tower at El Centro, California. Thousands of these kits were produced between 1975 and 2006, when Koch’s operations were ended.

Several individuals who are now employed by Formworks Plastics, Inc., were a part of the initial Koch CNU-129/P team at H. Koch & Sons.

George D. Little, Formwork’s Quality Assurance Manager, began his career at Koch in 1974 and was at first a production inspector and later, Vice-President of Quality Assurance. Every CNU-129/P ever produced has been subjected to Mr. Little’s scrutiny. He was instrumental in developing the test procedures used for in process inspection and final acceptance testing of the survival kits. Margaret C. Martin started her employment at Koch in April, 1975. She soon became a production lead person at Koch and was involved in the fabrication and assembly of both individual components and the final assembly of every one of these kits. She developed assembly techniques which have been incorporated into the assembly procedure documentation that is a part of the shop instructions. John F. McNaughton began working at Koch on the same day as Mrs. Martin. He was Material Control Manager when the first kits were produced at Koch, and later, became the Program Manager for all of the rigid seat survival kits produced by Koch. Part of his responsibilities included visiting user units within the USAF to assure that they received the support needed to properly maintain the kits. In 1992, Mr. McNaughton was elected President of the SAFE Association having served in several capacities both at the local (Southern California) and national levels. Mr. Samuel Edwards came to H. Koch in the 1990s. He was Maintenance Supervisor and was responsible for the upkeep of Quality Assurance machinery, most notably, the survival kit test stand. Mr. Edwards’ skill was instrumental in the fabrication of an improved test stand for Formworks Plastics’ survival kit program.

In 2007, following the closure of H. Koch & Sons Co., Formworks Plastics acquired tooling, drawings and documentation associated with the manufacture of the CNU-129/P Survival Kit Assemblies. After several years, the U.S. Government solicited bids for the fabrication of these kits by our armed forces. Formworks Plastics was the successful bidder and in early 2013 was awarded a contract for more than 125 of these devices. Subsequently, Formworks Plastics has become the sole source for the kits. A team was formed at Formworks’ Orange, California facility. With the assistance of the four persons mentioned earlier and existing Formworks employees, work on the program was begun. During three short months, a discreet assembly area was constructed, a secure stockroom was configured and the documentation was put into Formworks’ accepted format. Many of the suppliers who had been used in earlier contracts were located and employed. Formworks Plastics has a distinct advantage inasmuch as nearly all of its suppliers are located within thirty miles of our location. The Formworks team produced the First Article survival kit in less than six months from the time of contract award. It was presented to the test laboratory at Wright-Patterson Air Force Base, Ohio and was approved for production.

Production of this order concluded early in 2014.

………………………………………………………………….

025-750000-5 SURVIVAL KIT COMMON REFERENCES

The Ejection Seat Survival Kit is known by the following Part Numbers: NSN 1680-01-065-6644 / CNU-129/P Survival Kit / 025-750000-5